In liquidation since December 9th, 2020

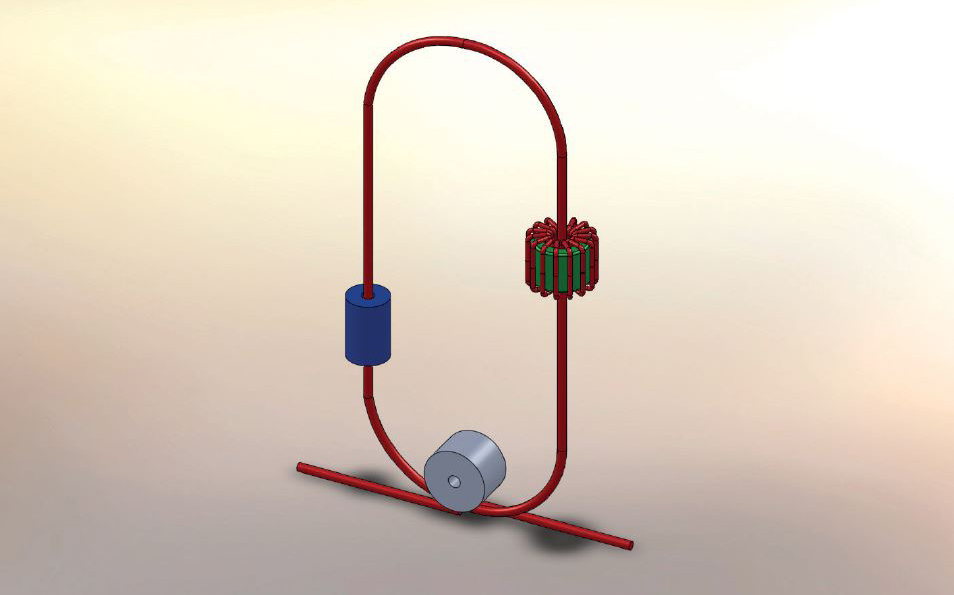

Development, production and selling of systems and machines for inline heat treatment in principle of longitudinal field, cross field and transformation

Induction Heating Principles

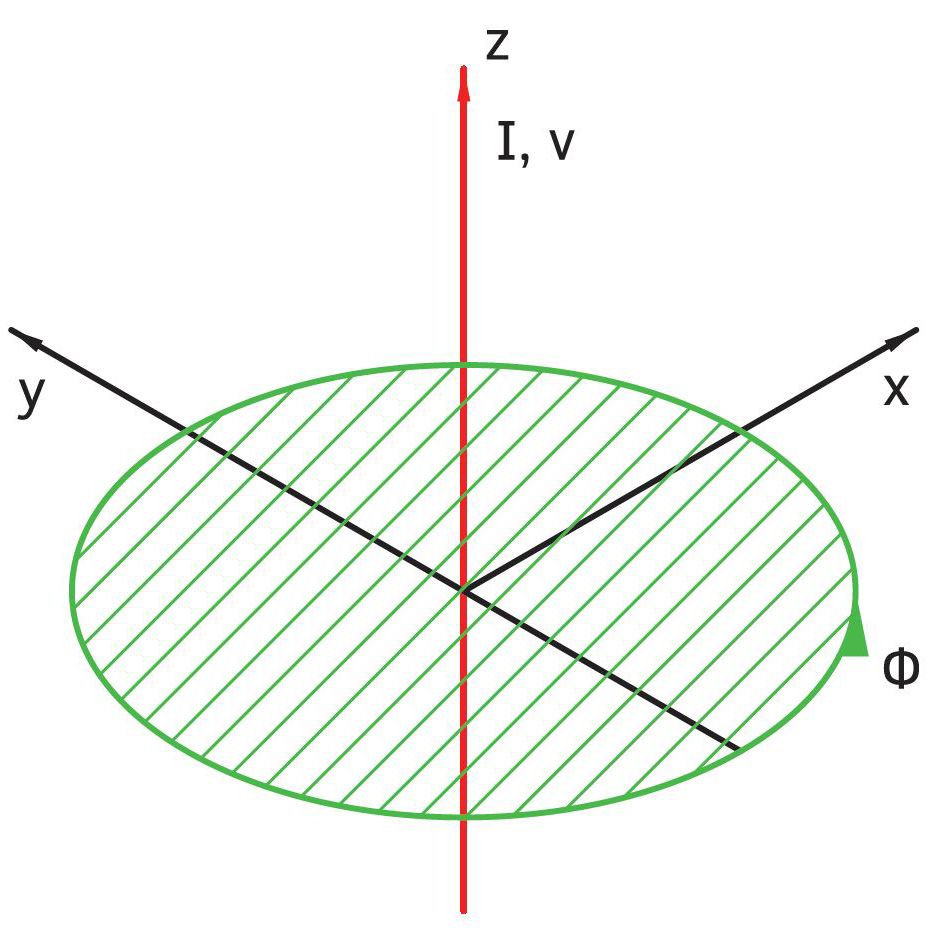

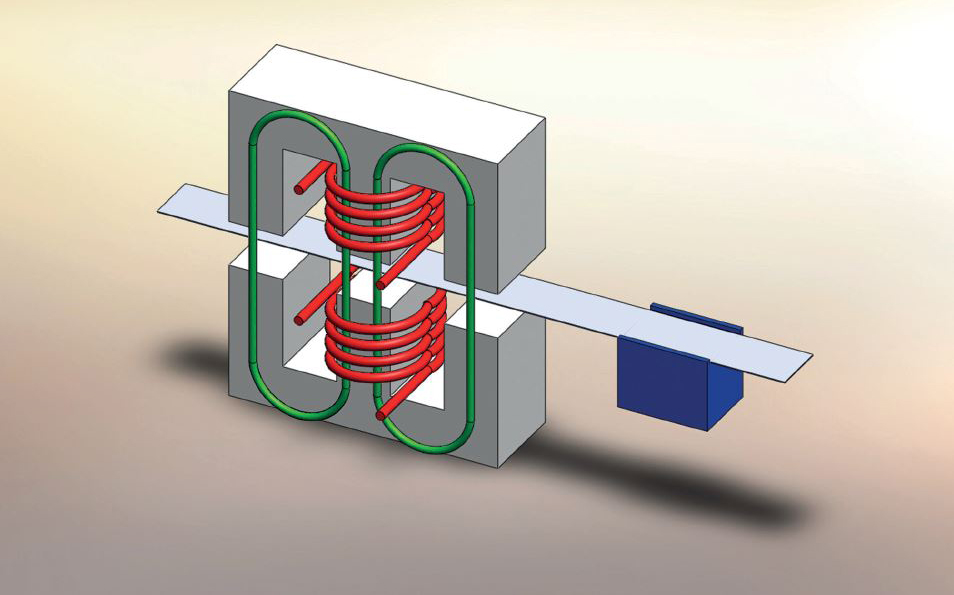

The magnetic flux Φ made a circle in the core. Material flow (wire) with speed v and the annealing current I are parallel and rectangular to the magnetically flow Φ.

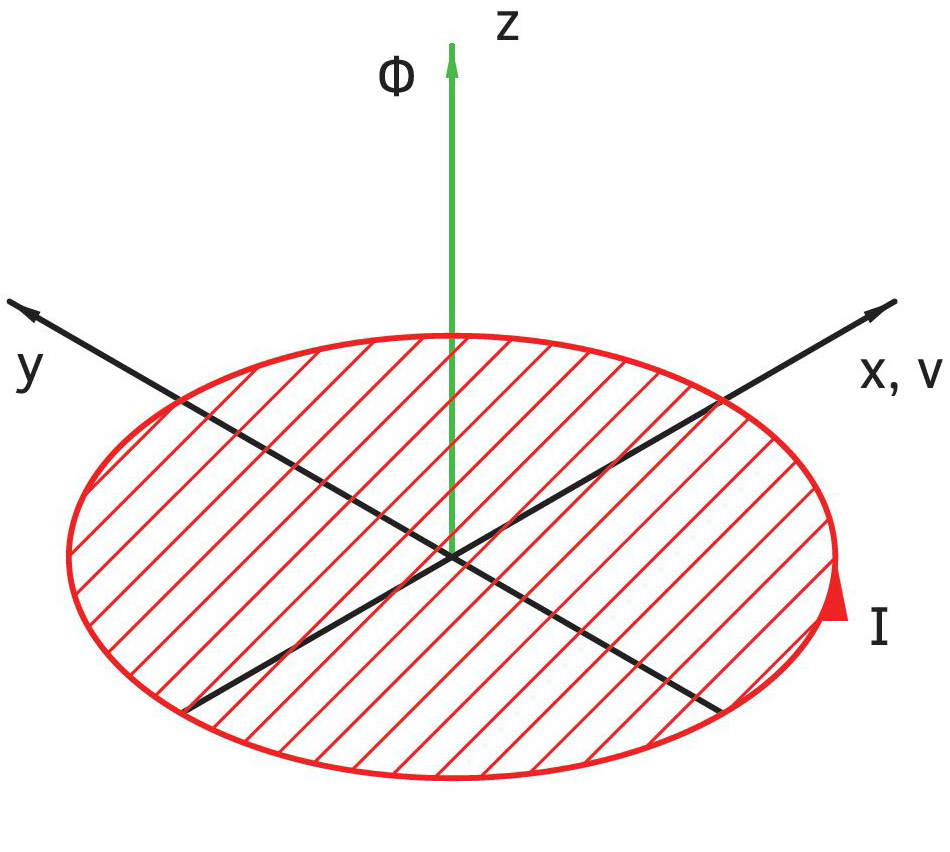

The magnetically flow Φ is induced by the primary current in the windings of EE / CC-core and rectangular to material flow with speed v and annealing current I. The annealing current makes a circle in the material rectangular to the magnetically flow Φ.

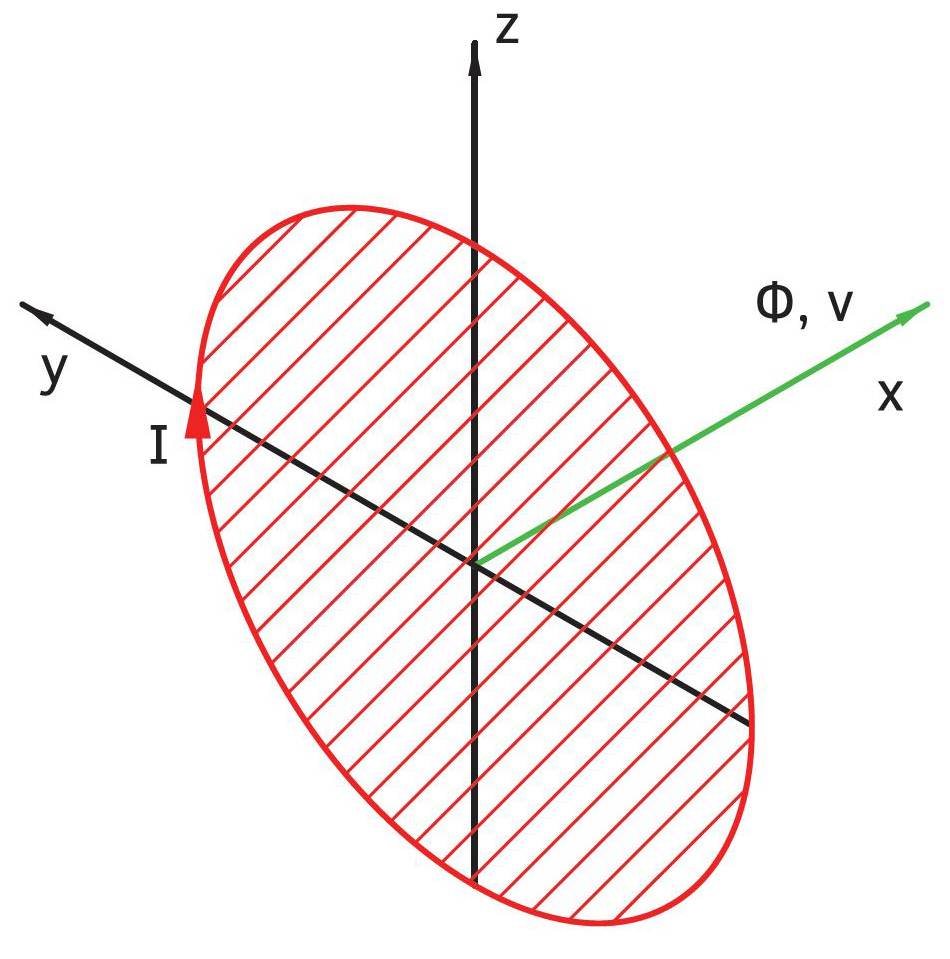

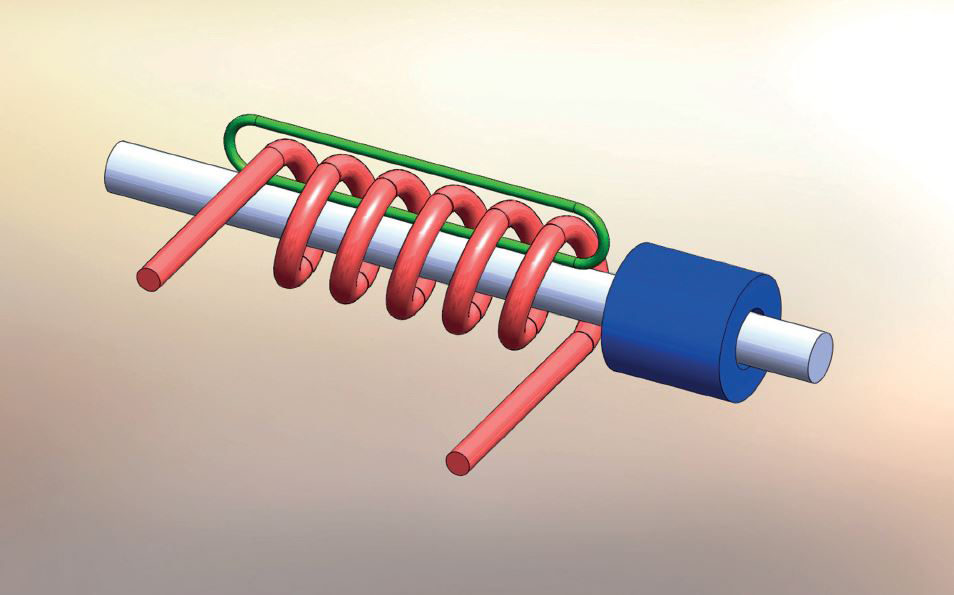

The magnetically flow Φ is induced by the primary current in the windings of cylindrically coil and in direction of the axis of the coil. Material flow (wire) with speed v is rectangular to the annealing current I and parallel to magnetically flow Φ. The current made a circle in the material.

Characteristics of induction annealing (especially of the transformer principle )

- High voltage and a lower current for the energy transfer

- Contact less inductive energy transfer in the loop and conductive heating

- Very High efficiency > 90 %

- In praxis proofed mathematic-physical concept for dimensioning based on the material properties depend of temperature

- Simple line construction

- Fewer wearing parts with a long life time

- Very high surface quality

- Suitable for a wide range of materials

- copper and copper alloys

- nickel and nickel alloys

- special materials and composites

- The lines can be configured for either round or flat wires.

Our services

- Design of process-integrated contactless heating systems for all your needs

- Extensive experience with various physical operating principles for cost-effective systems with high efficiency and small size

- Feasibility studies for difficult processes based on mathematical and physical dimensioning tools

- Long-standing industry, material and process knowledge

- Design and construction of heating systems with defined interfaces

- Rapid implementation of individual solutions based on our modular conception