Transformer

Inductive-conductive heat treatment units (transformer)

Induction heating of round and flat wires (transformer)

Induction heating of round and flat wires (transformer)

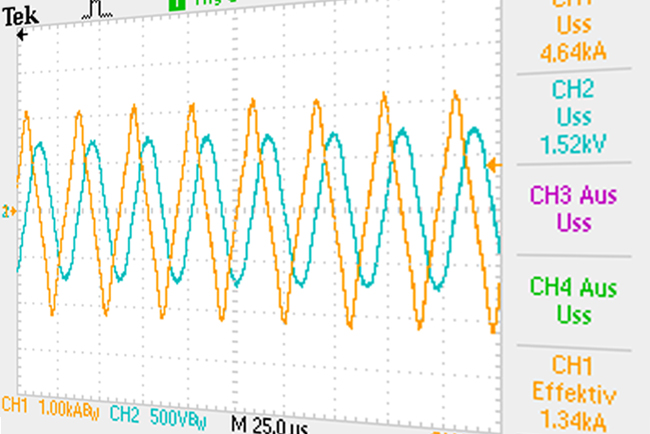

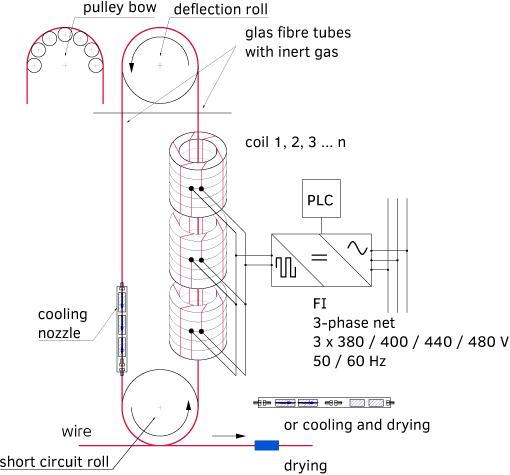

The inverter (FI) is powered by the 3-phase mains and transfers the AC voltage into a DC intermediate circuit voltage by an unregulated B6 bridge. Special components generate a square wave voltage with pulse width control. This voltage is applied to the coils and is transformed into the appropriate annealing voltage. Thus, a number of metals and alloys can be annealed (especially based on copper; such as brass, bronze and nickel silver but also other materials), in form of wire or as narrow strips.

This kind of equipment is successfully on the market since 2001. Dr Menge has the patent rights for this technology.

The equipment can be built in various sizes, and in right-left or the left-right variants suitable for diameters in the range of 0.1 ... 4.5 mm.

Types of Machines

Types of Machines

| Annealer | Induction | Size SCR [mm] | Round/Flat | Max. Current FI | Direction | Build | |

|---|---|---|---|---|---|---|---|

| A | I | 420 | R | 1200 | L | AI420R1200L | |

| A | I | 420 | R | 1200 | R | AI420R1200R | |

| A | I | 420 | R | 600 | L | AI420R600L | 3 |

| A | I | 420 | R | 600 | R | AI420R600R | 2 |

| A | I | 250 | R | 300 | L | AI250R300L | 4 |

| A | I | 250 | R | 300 | R | AI250R300R | 1 |

| A | I | 170 | R | 150 | L | A170R150L | |

| A | I | 170 | R | 150 | R | AI170R150R | 2 |

| A | I | 120 | R | 50 | L | A120R50L | 2 |

| A | I | 120 | R | 50 | R | AI120R50R |